Beer

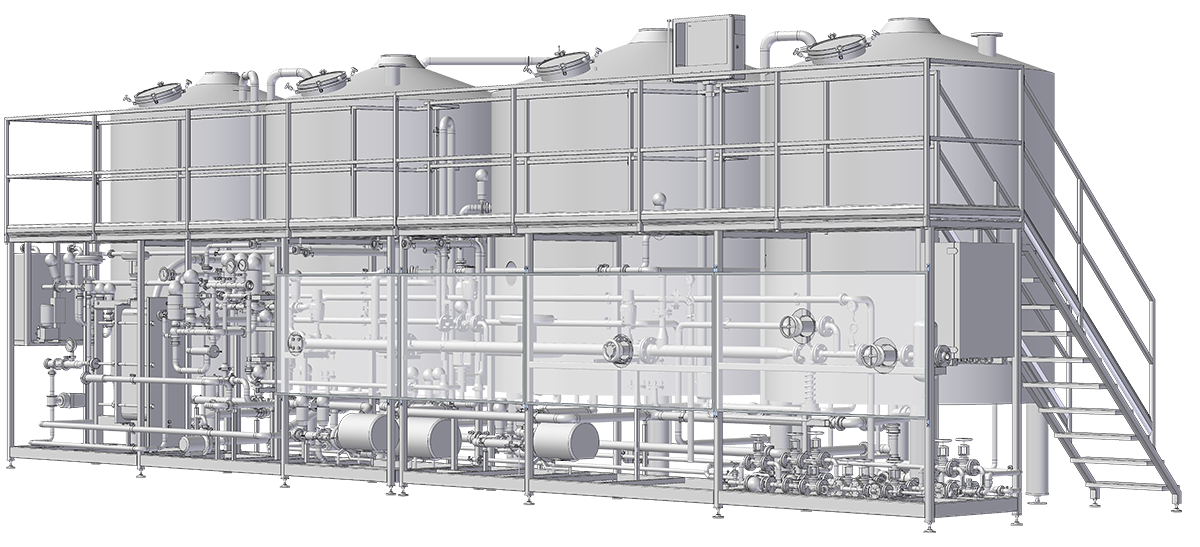

AN ANCIENT ART IN A MODERN TECHNOLOGICAL SOLUTION. BREWERIES'S SYSTEMS FOR SMALL PRODUCTIONS OR LARGE VOLUMES.

FRAU also designs, builds and sells its own solutions for the world of craft beer; as process specialists and with the support of experienced master brewers we have developed a number of product lines bearing in mind the factors that characterise the world of brewing today:

flexibility, "tailor-made" solutions in terms of configuration and on field study , efficiency and automation configurable on several levels seeking to put the brewer in the best technological conditions to develop and test various recipes and at the same time guaranteeing excellent repeatability of the studied product.

For many years now, "craft" has been synonymous not only with high quality raw materials but also with equipment that allows great freedom in managing the process and a degree of automation that is comparable to the most complex plants in the food and beverage industry.

Our solutions range from the individual brewing room to a complete production plant configuration starting from malt management to bottle/keg/can packaging.

We are able to study and provide the optimal configuration after a careful evaluation of the customer's needs: our offering ranges from 2 vat configurations which are already optimised for double boil (brewpubs and small productions) up to 3-4-5 vat solutions with process buffer for multiple boils on 2 or three daily shifts. The range of volumes per brew goes from 5hl to 30hl, the automation on different levels so that the presence and intervention of the brewmaster is proportional to the production effort and economic investment.

From the perspective of the complete solution, FRAU's product/service proposal consists of:

• Management system (or single load) of base malt and speciality malts

• Brewhouse

• Fermentation / Maturation tanks

• Storage and process water tanks

• Auxiliary equipment (steam generator, chiller, compressors, buffers, priming tanks...)

• Product separation and treatment equipment (centrifuges, filters and pasteurizers)

• CIP cleaning

• Automation and remote control

• Study of the installation layout

• On-site installation service (technicians and materials)

• Commissioning and training

All FRAU equipment are tested in-house before shipment and assembled at the customer's premises.